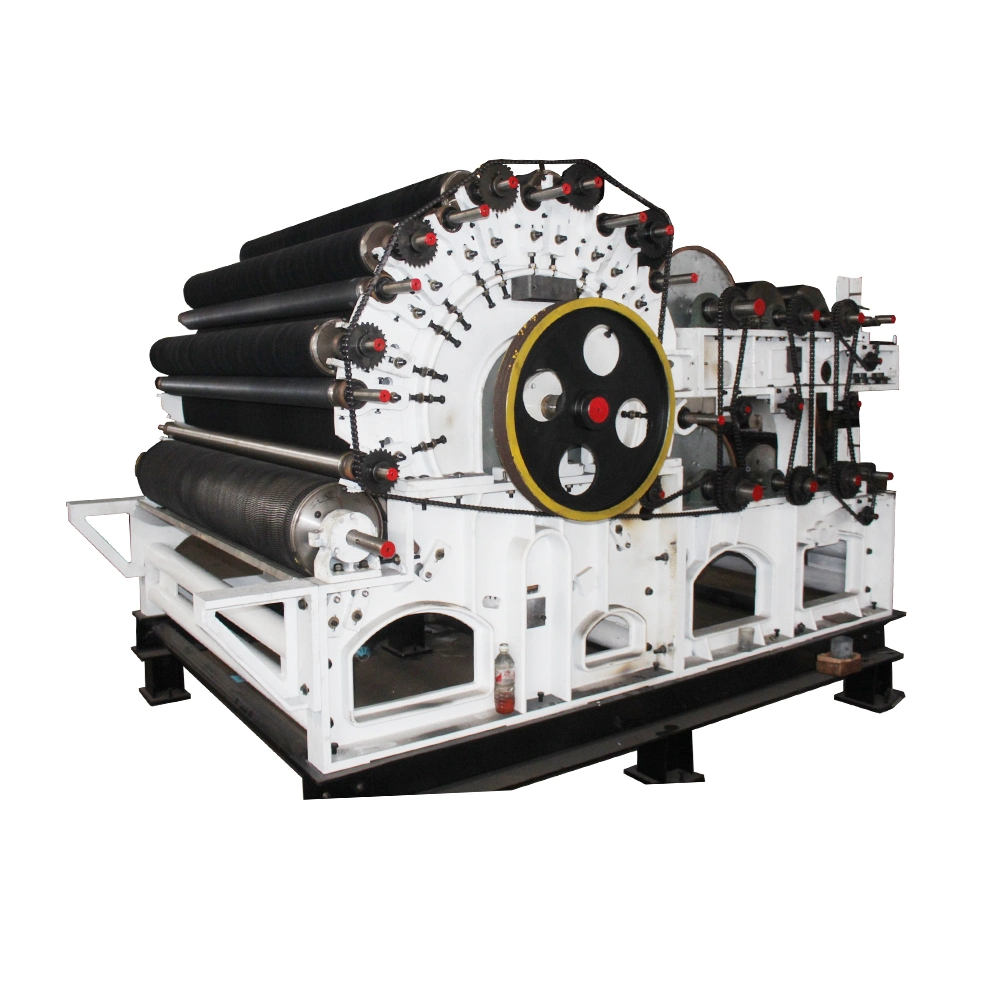

High Capacity Nonwoven Staple Fiber Single Cylinder Double Doffer Carding Machine for Making Nonwovens

High Capacity Nonwoven Staple Fiber Single Cylinder Double Doffer Carding Machine for Making Nonwovens Introduction: We ;

Basic Info.

| Model NO. | HN |

| Warranty | 1 Year |

| Working Width | 1550-2500mm |

| Transport Package | Standard Packing |

| Trademark | HN |

| Origin | Shandong Province, China |

| HS Code | 8445119001 |

Product Description

High Capacity Nonwoven Staple Fiber Single Cylinder Double Doffer Carding Machine for Making Nonwovens

Introduction: We manufacture a kind of muti-function carding machine which can't only process wool and fiber but also new and old cotton by our experiment and research over and over again. It perfect combine all the advantages of carding machine and cotton carding machine, get rid of the defect of old carding machine and cotton carding machine processing products single . Can be processed: old and new cotton, wool, chemical fiber, old and new woolen yarn ,etc.

Multi-function carding machine advantages:

(1)high speed carding make fibre full card and web more even

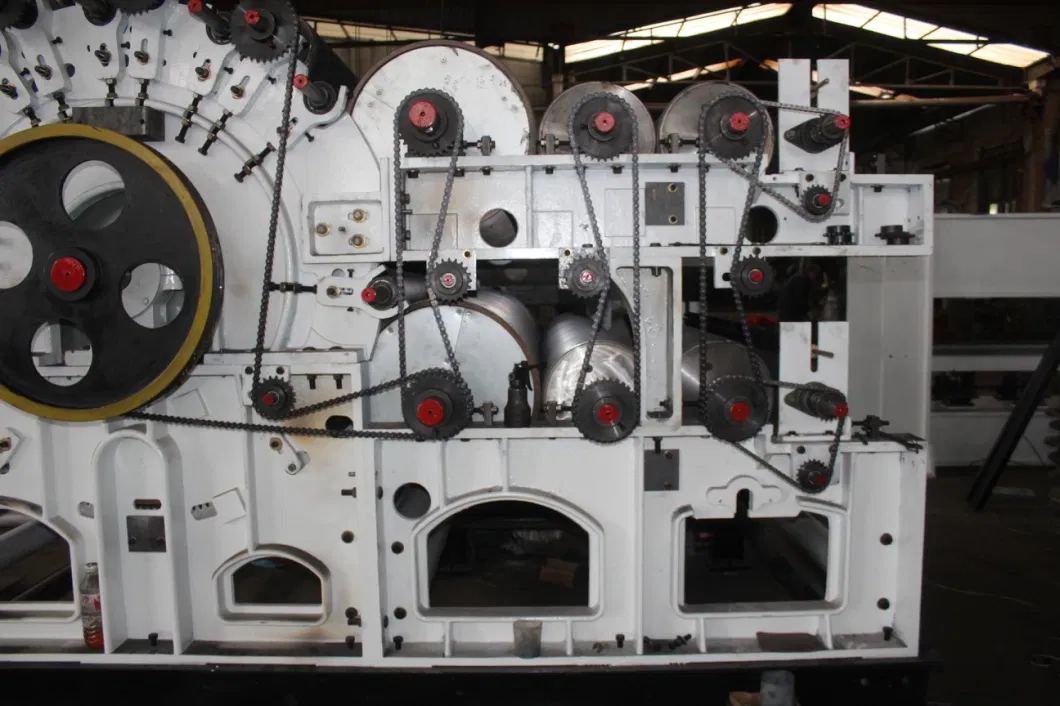

(2)adopt duplex bearing enclosed shaft sleeve, high precision,almost no shaft head lap-ups

(3)Center induced draft, balance the internal pressure and suction side system

(4)Adopt stainless steel rod type to leak

(5)Whole machine adopt touch screen to centralized control,frequency changer.

(6)High platform and fence cylinder, opening and closing the top cover

In addition, machinery environmental protection:

there is dust collection device to ensure the health of workers;

Shortcut: a molding to save cumbersome manual elaborate;

Safety: machine shield to ensure the workers' safety, and provides customers with more perfect production equipment.

| NO | ITEM | DESCRIPTION |

| 1 | Model | GMCD2-155 |

| 2 | Raw materials work on | Processing of raw materials from feeding machine, the output fiber layer |

| 3 | Working width | 1550 mm |

| 4 | Production capacity | 180 kg/h(Reference 6 d first-grade product chemical fiber) |

| 5 | Fiber raw materials requirements | 3~15D×38~65mm |

| 6 | The speed of the output fiber layer | ≤40m/min |

| 7 | Total power | ≈21.5KW |

| 8 | Main body | High quality castings (HT200), are subject to high temperature stress after processing and precision machining with a mix of profile stays |

| 9 | Feeding roller | With a pressure roller feeding uniformity.Feeding roller: 4sets , φ65mm |

| 10 | Metal detectors | Equipped with metal detectors, feedback and control power and warning |

| 11 | Diameter of Cylinder &doffer &mixed and disorderly roller | φ1230 mm, double doffer diameterφ492 mm, mixed and disorderly roller diameter: φ295 mm |

| 12 | No of groups | There are 5 carding working groups, so can get a very good carding effect |

| 13 | Dust collection points | There are 4 dust places |

| 14 | Working shield | Working shield with transparent organic glass, a mechanical rotation can be observed during it running |

You may also like

Send inquiry

Send now